“Top 10” Readiness Knowledge-Box “Essentials”…

Published on February 12, 2010 in "Top Ten" Lists | No Comments

…for cross-functional teams.

Suppose you were asked to form a cross-functional team to complete a mission within your organization or for a customer. Suppose also that you weren’t told anything specific about the mission, only that it would be challenging and complex. What types of knowledge or skill sets would you want your team members to possess? We regularly talk to team members in different industries and organizations and they give us insight into the skills and knowledge they find most valuable. Below is a “top ten” list of our conclusions from many discussions on the subject. To be sure, the list is controversial, opinionated, and highly dependent one’s own unique circumstances and focus. We hope it stimulates critical thinking and helps teams identify their own list of the essential knowledge most useful in completing their mission — on-time, within budget, according to specification, and as expected.

(rankings are shown in alphabetical order and are not prioritized)

“Top Ten” Readiness Knowledge-Box “Essentials” for Cross-Functional Teams

| 01. Benchmarking |

| 02. Emergency Management |

| 03. Income Statement |

| 04. Lean Production |

| 05. Learning Curves |

| 06. Project Management |

| 07. Six Sigma |

| 08. Solution Selling |

| 09. “Wisdom of Crowds” |

| 10. “How to Win Friends & Influence People” |

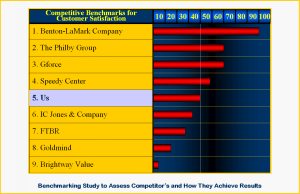

1. Benchmarking

- Benchmarking is the process of understanding and analyzing what others are doing to address a particular problem or to achieve superior results. Benchmarking can uncover solutions, techniques, “best practices,” and performance metrics that the team can use to address issues they are facing. Typically, when a team is faced with a particular challenge, they conduct a benchmarking study to understand what other organizations might be doing to address the same or similar situations.

- Why: Benchmarking can help teams quickly find solutions to the problems they face. It makes use of the learnings and knowledge of others to minimize the time, cost, and risk of having to find solutions on one’s own. This gives teams confidence in their approach and a high degree of probability that they will achieve the desired results.

Click Image to Enlarge

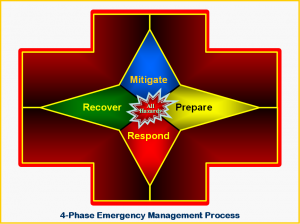

2. Emergency Management

- Emergency management is a 4-phased assessment and implementation process to Mitigate, Prepare, Respond, & Recover from potential emergency situations or incidents that the team may face. This often is used for natural or man-made disasters such as hurricanes, terrorist attacks, floods, fires, etc.. But it should also include activities that may be more directly affected by the team such as product failures, equipment breakdowns, job-site hazards, slips & falls, etc.. The consequences can be death, dismemberment, criminal convictions, jail time, financial penalties, lost business, and more. It can destroy lives, businesses, and reputations.

- Why: Do not wait until an emergency happens. Take steps to prevent it and know exactly how to respond should the unthinkable happen. Working with team members that have an “emergency management” mind set may eliminate the possibility of a failure or disaster or enable the team to quickly respond and limit the damage should an incident happen.

Click Image to Enlarge

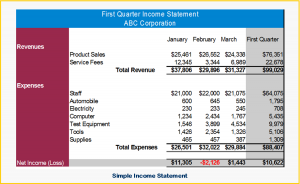

3. Income Statement

- An income statement is an accounting report that shows the monies coming in (e.g., revenue, sales, donations) and the monies going out (e.g., expenses, costs) to give the net income (e.g., profit or loss). It can also show projected income, expenses, and profits (or losses) for different time periods, with assumptions and risks.

- Why: Money is the lifeblood of any business. To continue operating, a business must constantly understand and control its process for generating income, and its expenses. The income statement can be used as a forecasting and planning tool to manage the actions, assumptions, priorities, and risks of the organization. A team operating with an “income statement” awareness can work proactively to affect its financial results.

Click Image to Enlarge

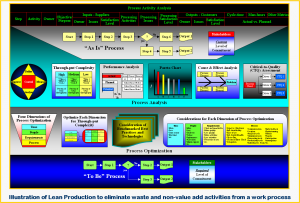

4. Lean Production

- Lean Production is a framework for producing things efficiently, with minimal wasted input. It focuses efforts on finding value added activities, while allowing for flexibility to accommodate the normal changes and uncertainties of any process (changing priorities, quantities, due dates, etc.). It offers a set of tools and metrics for ensuring perfect order fulfillment – the right things, at the right time, in the right place, in the right quantity, and the right quality.

- Why: Regardless of what you produce (products, services, paperwork, etc.), understanding lean production practices can help you structure your work process so your job can be done more efficiently, faster, correctly, at less cost. Applied lean thinking improves the team’s final product by making jobs easier to understand, do and manage.

Click Image to Enlarge

5. Learning Curves

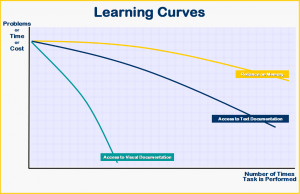

- Learning curves tell us that the more we do something, the better at it we get, and the more knowledgeable we become. This implies several things. With experience comes knowledge that enables us to better understand and control the situation (do it faster, more correctly, at lower cost, greater predictability in the outcome, etc.). With experience comes greater understanding of the factors that can influence the process, both positively and negatively. Additionally, learning curves imply that there is also a “forgetting curve,” that the longer we wait in between doing something, the more likely we are to forget how best to do it.

- Why: While the concept of a learning curve may be obvious, it can have a significant impact on managing team performance. Awareness of learning curves can help the team set rational expectations for success. This is especially true in judging the performance of a new team member, assessing progress during development and innovation activities, or when trying to enter a new market, or produce a new product. Learning curves can help teams take realistic assessments of early failures or slow progress. They can help find patience and confidence to overcome adversity and discouragement in the pursuit of success. They can provide encouragement and proper perspective when results seem disappointing. Perhaps most importantly, they can help the team make wise investments in effort, time, trial & error, test & fix, or training to gain the experience they need to achieve success. A failure to understand learning curves can lead to poor decisions, unrealistic project plans, discouraged team members, premature program cancellations, and missed opportunities.

|

|

Click Images to Enlarge

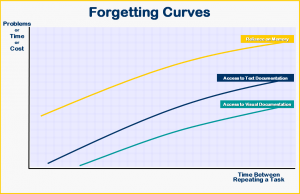

6. Project Management

- Project management is a disciplined and structured process for planning and completing tasks to achieve a particular goal. The more complex the project, the more resources may be needed to complete it, the more difficulties may be encountered, and the more risk there may be to a successful outcome. Project goals have requirements that involve schedules, budgets, specifications, and expectations for how things are to be done.

- Why: Most everything we do is a project, in one form or another. Knowledge of project management helps team members stay focused, coordinated, and make deliberate, intentional progress towards successful completion of project goals. Without some form of project management, team members can easily get defocused, distracted, and redirected. Projects can languish. When a project does get completed, it may be over-budget, late, and not meet specifications or expectations.

Click Image to Enlarge

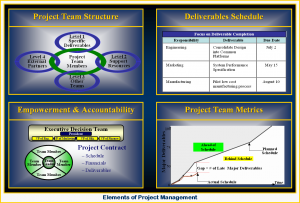

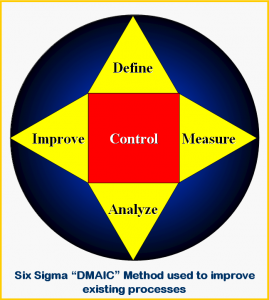

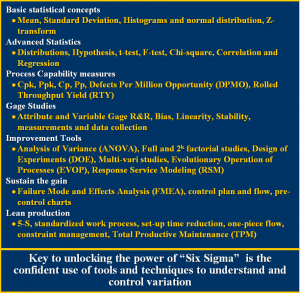

7. Six Sigma

- Six Sigma defines a methodology for applying powerful problem solving tools to control process variation. A variable process is one that produces inconsistent or “out-of-spec” results and is considered “out of control.” Controlling process variation is the key to ensuring process outputs that meet required specifications and quality levels, maximize productivity and efficiency, and Minimize cost. A controlled process ensures that the same desired output is produced every time. Where lean production methods help in designing a good process, Six Sigma helps keep that process under control so it produces the desired output.

- Why: The methods and tools used in Six Sigma have numerous applications. They provide a structured, scientific, step-by-step method to problem solving and serve as a basis for good decision making. Six Sigma methods provide order and clarity when dealing with complex problems characterized by chaos and uncertainty. When a team member is faced with a challenging problem and the solution is not clear, or wants to be sure that a particular process will generate a desired output, knowledge of Six Sigma methods can provide answers and very helpful direction.

|

|

|

Click Images to Enlarge

8. Solution Selling

- Solution Selling is a consultative sales process for finding “win-win” solutions to customer problems that also satisfy the needs of the seller. It is a problem solving process, a negotiation process, a relationship building process, and a guidance process leading to better decision making. Beyond mere product promotion or acting out of self-interest, Solution Selling requires introspection and insight into one’s own capabilities and a deeper understanding of the real needs of a customer. It provides direction and guidance through the sales process to expedite the decision process and help ensure a favorable outcome.

- Why: The value of Solution Selling goes way beyond consultative sales to customers. We are all involved in “selling” to some degree, either directly with a customer or when presenting our ideas to others. Solution Selling is about finding common ground and value. It is a framework for working with others, some of whom may not want to work with us. It is a skill that helps us look beyond ourselves to find out what is also important to others. It is a means of finding solutions in the workplace and can help promote good working relationships among team members. It is a “win-win” negotiation process that can ultimately lead to better decisions, greater value creation in our products and services, a more harmonious work environment, and better relationships with team members, suppliers, and customers.

|

|

|

|

Click Images to Enlarge

9. “Wisdom of Crowds”

- “Wisdom of Crowds” is a group decision making process formulated by James Surowiecki. It shows that group decision making, properly applied and managed, can lead to better decisions than those made by an individual alone. Wisdom in decision making comes about when there is diversity of opinion, independent thinking, decentralization (specialists with “local” knowledge and involved), and aggregation (collaboration and discussion occurs amongst participants).

- Why: For complex problems that teams often face, understanding the need for group decisions, that follow “Wisdom of Crowds” criteria can make the difference between success or failure. Often, major and complex decisions have irreversible consequences. It is important to understand what decisions are best made by individuals and what ones should be made in a group using a wise crowd process. It challenges our comfort zone by seeking the opinions of “experts” who we may disagree with, but whose perspective and insight we would be wise to consider. Establishing milestones and forums for such decision making (e.g., a stage-gate process, or milestone driven project reviews, Go/No-go points, etc.) can help a team better manage its mission.

Click Image to Enlarge

10. “How to Win Friends & Influence People”

- “How to Win Friends & Influence People” is a book by Dale Carnegie on relationships, persuasion, leadership, feedback, and communication.

- Why: The book provides timeless advice on how to get along with others. This is especially helpful in the work environment where assignments are made, where we often have little choice regarding who we have to work with, where people are held accountable and their actions are reviewed and scrutinized. Having knowledge and skills focused on the importance of relationships and a demonstrated ability to get along with people is invaluable to the well being of the team.

Click Image to Enlarge

DMW

Copyright © 2007-2011 TeamReadiness, Inc.